What are the documents for the production of beer. Opening your own brewery: legal nuances, production features

The commercial production of alcohol seems dark forest... Some excise taxes, EGAIS, reporting, do you need a license? What if you just want to put on an apron and brew craft beer? Doctor Guber manufactures brewing equipment for home and commercial use and will tell you how to start your brewery.

Can I brew beer in the kitchen?

To begin with, let's pay attention to a few key points to clarify the situation:

- It is not possible to make beer on a commercial basis using home-made equipment. The equipment must have a quality certificate.

- You cannot brew beer for sale at home or in a garage, because you can only engage in commercial activities in a non-residential fund.

- No beer production license required. You will only need it if you decide to make something stronger.

What documents are needed?

The main law that regulates the production of beer and spirits is Federal Law No. 171 "On State Regulation of Production and Turnover ethyl alcohol, alcoholic and alcohol-containing products ". All links to laws, instructions and sample documents will be at the end of the article, so read without distraction.

To open and launch beer production, you need following procedures and documents:

1) Choice of legal form. To open a brewery, you need to register your LLC. Individual entrepreneurs can sell beer, but not produce. In article 11, paragraph 1, we read: “production and circulation of alcoholic beverages (with the exception of retail sale of beer and beer drinks, cider, Poiret, mead) and alcohol-containing food products carried out by organizations ". That is, you first need to open your LLC. Article 11 paragraph 1.

Attention: when registering an LLC, you must indicate the appropriate OKVED codes that allow brewing beer. You can choose as many codes as you like, so take with a margin.

2) Documents for registration of the brewery. The equipment you work on must be properly manufactured and decorated, otherwise it is simply impossible to register a brewery. The brewery should have serial numbers... A set of documents is also required: a declaration, a test report, technical specifications and a passport for the equipment. These documents are provided by the equipment manufacturer.

3) Calculation of the capacity of the main technological equipment. The calculation is necessary so that Rosalkogolregulirovanie (RAR) can understand whether it is necessary to install meters on your equipment. If your equipment allows you to produce more than 300 thousand decaliters per year, you will have to install meters. The calculation is submitted to the PAP in writing and in electronic format... The answer is within 30 days.

4) Application for the commencement of food production activities. Beer, beer-based drinks, cider, Poiret, mead are alcoholic products. Therefore, if you want to produce them, you need to notify PAP about it.

5) Declaration of conformity for the produced beer. This document confirms that you are brewing beer and that drinking it is safe for your health. The declaration includes TU ( technical conditions) and TI (technological instruction), compiled by the chief technologist of the brewery, as well as analyzes confirming the safety of the product. You can get the declaration privately by contacting one of the accredited declaration and certification centers.

6) Connection to EGAIS... EGAIS takes into account all produced and sold beer, which should exclude counterfeit products from circulation. To connect to the system, you will need:

- Computer connected to the Internet

- UTM (universal transport module) EGAIS is a program that is required to transfer data to the Rosalkogolregulirovanie server about your purchases and sales

- JaCarta crypto-key is a unique electronic key that is required to work with the system. Buying a crypto-key is the first step to connect to EGAIS.

- Inventory program

- Reinforced electronic signature- writing to a crypto-key issued by EGAIS.

Installation of specialized equipment is the competence of EGAIS employees.

A brewery employee who will use the EGAIS system must undergo compulsory training in one of the certified organizations. Training can be done both internally and remotely ..

7) Notification to SES and fire inspection. Since beer is a food product, the SES must make sure that the production complies with sanitary standards. Your premises should be "accepted" by the district fire inspection. It is necessary to notify her of the start of work and agree on a project that will indicate emergency exits, the location of fire extinguishers and a pressure tap, etc.

8) Production control program. This is a pretty formal document that shows that you really know how to do your thing. The production control program includes:

- List of controlled stages and parameters of technological processes.

- Frequency of production control, a list of its activities and responsible persons.

- Schedules and modes of sanitization, cleaning, disinfection, disinsection and deratization of industrial premises, equipment and inventory.

- Schedules and modes of equipment and inventory maintenance.

- Measures to prevent and identify violations in the organization and implementation of production processes.

So, briefly on how to open a brewery:

- Register LLC;

- Own equipment, obtain a declaration of quality for beer;

- Buy or rent premises for at least 1 year;

- Submit power calculation to RAP;

- Connect to EGAIS;

- Notify SES and Fire Inspectorate;

- Submit an application for the commencement of food production activities and a notice of the commencement of turnover in the territory of the Russian Federation.

In the following articles, "Dr. Guber" will tell you what equipment you can start with and what kind of beer to brew in production.

In this article:

Beer is a barley-malt drink with a hop aroma, pleasant bitterness, and the ability to foam when bottled. Due to its unique taste, thirst-quenching effect, the intoxicating drink is in high demand among the population. And therefore, very tough competition has formed on the beer production market. But, despite this, an enterprising businessman who decided to open a brewery can always organize a profitable and promising business.

In order to start your own business, you do not necessarily need large investments. However, to carry out this activity, it is necessary to obtain a spectrum permits, certificates. Administrative barriers are difficult to overcome, especially for a budding entrepreneur. Therefore, further we will consider the features of registration of permits.

How to put a microbrewery into operation

In order to put a mini-brewery into operation, you must obtain the following documents for the production of beer:

- Permits from FEZ and Fire Inspection, Gosenergonadzor;

- Carry out licensing of beer production and visit the STI department. A business involving the production and sale of beer is not subject to licensing. However, the government has issued a new regulation that stipulates that beer production at the federal level is subject to licensing. To obtain a license, you must write a request to tax office... The beer production license is issued within three months.

- Hygienic certificate in sanitary and epidemiological supervision. The document is issued only after the hygienic assessment of the goods. The procedure can take up to 2 months.

Aspiring entrepreneurs should be aware that beer is an excisable commodity that is subject to an additional tax of 15%.

However, the administrations of some regions have created a law on the production of beer "On state regulation of the production of ethyl alcohol and alcoholic beverages", which assumes that each liter of a hop drink is subject to a tax of 300-400 rubles.

Technological process for the production of a hop drink

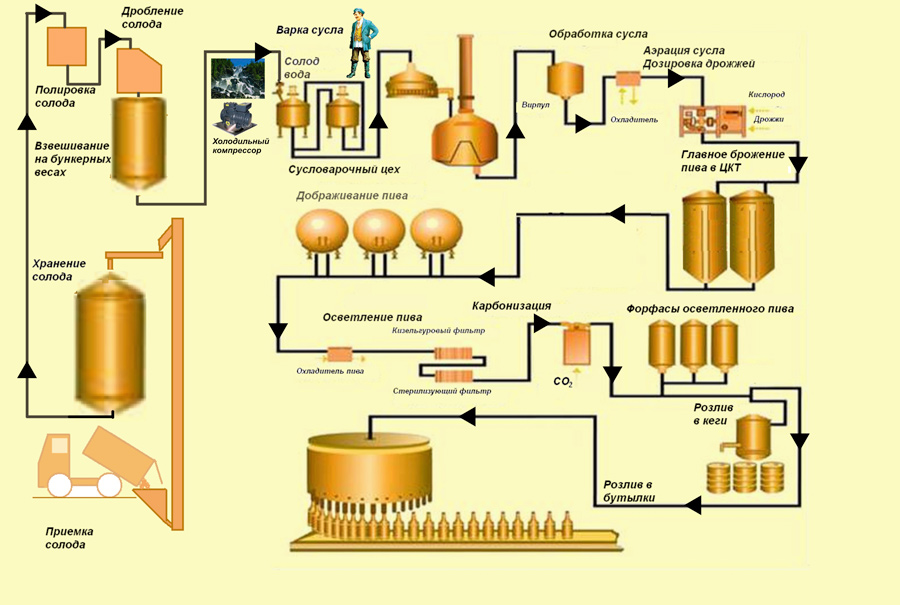

The hardware technological scheme of beer production is shown in the photo below.

The technological process includes the following main stages of beer production:

1. Preparation beer wort- preparation of malt for beer production, i.e. weighing the required amount product and its grinding. Then water is poured into the mash-brewing device and chopped malt is poured.

Then the mashing of the malt is carried out, which can be carried out in two ways:

- by infusion method;

- decoction method.

The candied mash is moved to filtration apparatus, in which its separation is carried out. After filtering the first wort, the spent grains are washed with water.

Traditional technology assumes that at the end the beer wort is boiled with hops for 1.5-2 hours and cooled to a temperature of 6-70 ° C. 2.

2. Fermentation of beer wort - carried out in a fermentation apparatus with the addition of brewer's yeast.

3. Extract of beer - takes place in hermetically sealed metal tanks for 11-100 days. The fermentation temperature and the duration of the process depend on the type of beer. As a result of aging, the beer becomes stronger, lighter and saturated with carbon dioxide.

4. After the organoleptic, laboratory and technochemical control is completed, beer is bottled. Automation of beer production allows filling the hop drink on special lines.

Equipment for the production of beer

Before you start purchasing equipment, you need to determine the capacity of the future enterprise:

- Plant for the production of beer, with a capacity of 50-500 liters - a mini-plant for the production of beer;

- Factory producing 500-15000 liters of beer - mini-brewery;

- The plant with a capacity of over 15 thousand liters is an industrial giant. Mini-breweries use the top fermentation method. As a result this method the intoxicating drink is infused in a container, and the duration production process decreases.

Microbreweries adhere to technological process based on bottom fermentation method... As a result of this technology, a hop drink is obtained more than High Quality... There is also a technological instruction developed by a research and production association, which considers the features of each production process.

To organize production draft beer such a list of equipment is required:

- malt grinder;

- filtration apparatus;

- pump for mash, wort and hot water;

- mash and wort apparatus;

- heat exchanger;

- water heating apparatus;

- pumps for young and finished beer;

- electric steam generator;

- fermentation tanks;

- hydrocyclone apparatus;

- refrigeration unit equipped with an ice maker;

- dispensing containers;

- yeast vats;

- control panel and control.

The technological line for beer production may include another set of equipment. The list of equipment depends on the type of beer produced, the name of the manufacturer, the type of malt and the characteristics of the technology.

Business plan for a mini-brewery

1. Purchase of raw materials and supplies

In order to purchase raw materials for beer production, you can consider such purchase options:

- Purchase malt from abroad. This type of purchase of raw materials is beneficial when large volumes are purchased.

- Buy malt from leading equipment suppliers or from the domestic market of the country.

The beer recipe determines the choice of raw materials for making a hoppy drink. Any kind of drink is brewed from yeast, malt, hops, water. However, there are various ways of producing special beers, in which the composition of the intoxicated drink can be modified.

The brewing process involves making malt. Malt production- a profitable type of business associated with brewing. If a novice entrepreneur wants to buy malt, then he needs to know that 50 tons of German malt are sold at a price of 0.55 USD. per kilogram. You can buy this raw material only in large quantities, over 50 tons.

Yeast for beer production can be purchased at the brewery or from a private brewer. It is more rational to buy yeast from a large enterprise, as a rule, it is of a higher quality.

To date, the following prices for raw materials and materials have been established:

- Water - 1 cubic meter m - about 11 rubles;

- Sewerage - 1 cubic meter m - 9 rubles;

- Malt - 1 kg - 8-9 rubles;

- Hops - 1 kg - 86 rubles;

- Yeast - 1 kg - 200 rubles;

- Electricity - kWh - 0.500 rubles.

Having compiled the material balance of beer production, and having carried out the product calculation, it is possible to determine the consumption of raw materials.

2. Purchase of equipment

To organize a mini-brewery with a capacity of 1000 liters of beer per day, you can purchase a set of equipment supplied by the Miass Machine-Building Plant, the cost of which is about 54 thousand US dollars. For the purchase of auxiliary equipment 200 thousand rubles are required.

Imported equipment for the production of beer, the price of which can fluctuate in the price range of 300-700 thousand. initial stages to buy production is not advisable and economically ineffective. However, an imported beer production line can increase the productivity of the mini-brewery and improve the properties of the hop beverage. Therefore, it is profitable to buy such equipment when the activity of the enterprise brings regular income and to obtain competitive advantages.

3. Preparing the premises for a brewery

Room preparation Is one of the main problems for private business leaders. In order to organize beer production and a business based on the commissioning of a mini-brewery, you can rent or buy premises. To accommodate a set of equipment, a room is required, the total area of which will be more than 150 sq. m. In view of the size of the equipment, it can be assumed that the beer production workshop will occupy about 100 sq. m. m, for warehouse you need 35 sq. m, for an office - 15 sq. m. Monthly rental costs will be about 25 thousand rubles.

4. Personnel

To set up a mini-brewery, you need about 10 specialists, among which there will be a director, a cleaner, 4 specialists employed in the main and auxiliary production, an accountant-cashier, 2 brewers, a forwarding driver. Monthly fund wages will be 250 thousand rubles.

5. Total costs of beer production

The total cost of organizing the brewery will amount to 3 million rubles.

6. Income from activities and calculation of economic indicators

In order to calculate the income from the commissioning of a mini-brewery, it is necessary to keep records of beer production on a daily basis. If beer is bottled at the enterprise, then their quantity and capacity are taken into account, if in kegs - the capacity and number of kegs.

The monthly income of the mini-brewery will be 200 thousand rubles, and the income for the year after deducting taxes will be 2 million rubles. The payback period for a mini-brewery is 1.5 years. Short term return on investment and high returns indicate that brewing is a profitable business.

Private breweries in recent times have become one of the most popular types of business. And this is not at all surprising, because it does not take much to open them. material costs, and the demand for products is consistently high.

Brewery

The popularity of the brewing business has led to quite high competition in this market. But even with her, this activity remains popular. This popularity is due to several features of mini-breweries.

- Firstly, opening a brewery does not require too much initial capital, which makes it affordable for the vast majority of entrepreneurs;

- Even with small sales volumes, such a business rarely becomes unprofitable - a mini-brewery can produce beer depending on demand, and its maintenance is also not particularly expensive;

- Thirdly, it is easy to draw up a business plan and forecast business development for such activities, since everything is easy to calculate.

Production volumes and cycles

But even so simple form business, like brewing, there is a certain division.

It is associated with the types of breweries, the main criteria for distinguishing which are production volumes and cycles.

On the first basis, mini-breweries are divided into:

- Those with a production volume of less than 5000 liters;

- Those whose production volume exceeds this figure.

In addition, breweries are:

- Full cycle;

- Shortened cycle.

Full-cycle enterprises are factories for the production of a hop drink in miniature. As a result, their opening requires a large investment of capital (from $ 150,000) and large areas.

In general, a mini-brewery does not require a large number equipment if it has a shorter cycle and produces less than 5,000 liters. You only need:

- A specialized boiler for boiling wort (instead of a boiler, a special stove is sometimes used);

- Fermentation tank;

- Filters for water from which beer will be made;

- Kegs for a drink;

- Sterile devices.

Registration of a brewery to a businessman

Russian legislation does not limit the circle of those who can open a brewery.

It can do and individual entrepreneur, and a legal entity.

The only thing is that in the constituent and statutory documents (registration certificate, charter, etc.), production and sale, wholesale or retail, of beer must be indicated as activities.

Naturally, if you are not registered as an individual entrepreneur or LLC, then you must do this in accordance with the standard procedure. You just need to remember when filling out the papers in the tax office to indicate the appropriate type of activity.

Taxes and fees

As for taxation, it is generally standard. You pay taxes in accordance with the system that you have chosen and the type of enterprise - flat tax or something else. But, there is one difference. Beer like any alcoholic beverage, is an excise goods. Therefore, you will also have to pay excise tax.

Do I need a license?

The laws of the Russian Federation require manufacturers of most types of alcoholic beverages to license their activities. But, beer does not belong to those types of alcohol that fall under the law "On State Licensing". At the same time, this does not prevent some administrations of the constituent entities of the Federation from still requiring a license on the basis of another legal act - the Law "On State Regulation of the Production of Ethyl Alcohol".

Launching the brewery

One of the most crucial moments when opening a private brewery is the selection of the premises. There are a number of requirements that mandatory should be considered:

- The microbrewery must not be opened in a residential area;

- The ability to work with three-phase current must be present;

- Internal walls should be covered with tiles up to two meters high;

- The ceiling is painted with water-based paint;

- Steam, air or water heating should be used.

The size and type of premises are not very fundamental - they depend on equipment and other parameters of this kind. The minimum area is considered to be 40 square meters... It can be a basement or a semi-basement.

A fashionable solution is to open an enterprise for the production of a hop drink at a restaurant, with partial removal of equipment to the hall.

As for the choice between renting and purchasing, it all depends on many factors. First of all, on the size of production. If it is large, then the purchase decision becomes the most justified. When calculating financial costs, you need to take into account the money that will potentially have to be spent on repairs or re-equipment of the premises. Perhaps in some cases it is more profitable to acquire real estate at a higher price, but spend less on its maintenance.

Equipment for mini-breweries

Mini-brew equipment is usually included. But nothing prevents you from buying it separately, if certain conditions require it. In fact, the set of things necessary for a mini-brewery is quite small. It necessarily includes:

- Two containers - for fermentation and additional fermentation;

- Filters for the water used in brewing;

- Refrigerating devices;

- A device for a sterilizing agent, usually in the form of a bath;

- Boiler for syrup making;

- Scales;

- Means for sanitary and hygienic processing.

Sometimes manufacturers can supplement this set with various special devices that speed up production or improve product quality. In this regard, the cost may differ several times. But in the basic version, it is quite low.

Certificates and inspections

Although brewing is not a licensed activity, an entrepreneur must still obtain a number of certifications and pass several checks. One of the most important documents is the product hygiene certificate.

This certificate is issued for a period of one to three years territorial body State Sanitary and Epidemiological Supervision.

The basis for issuance is a sanitary and hygienic check of the premises, equipment, products, as well as expertise normative documents enterprises.

The aforementioned authority also issues a permit for the production of beer. It is issued on the basis of the same check and conclusions of the State Fire Supervision Service about fire safety premises. The decision not to issue a certificate or permit by the territorial department can be appealed to the central State Sanitary and Epidemiological Supervision of the Russian Federation.

A microbrewery can be served by one employee

Recruiting staff can be as simple as complex. The fact is that a very small microbrewery can be served by one employee. And for big ones, of course, you also need more workers. The better the beer is supposed to be brewed, the more professional they should be. The minimum for a midsize business includes:

- Brewer;

- Cleaning lady;

- Driver;

- Sellers and sales representatives (the choice of one or the other depends on the availability of the retail sale of the drink).

Restaurant breweries also require technologist brewers. And with large volumes of sales, it is reasonable to hire a separate accountant, since we are talking about an excisable product.

Sales

Live beer has a potentially large sales market, but its size depends on the quality of promotion.

Enough good method sponsorship is considered.

Since the period of sale of this drink is short, it is important to establish its stable and timely distribution through stores or restaurants.

« Fixed payments to individual entrepreneurs: insurance and one-percent contributions, annual charges, taxation peculiarities How to independently close an individual entrepreneur in Novosibirsk: dismissal of employees, closing debts, closing an individual entrepreneur with debts »