What pipe is better to use for the fence. How to install corrugated fence pipes

The reliability of the entire fence structure directly depends on the material of the supporting frame.

Put wooden posts, and the fence on your site will last no more than 10 years. Wood, even antiseptic, is susceptible to decay.

Concrete is a more reliable option. But when installing such a design, difficulties arise with fastening the runs.

Drilling a reinforced pole is not easy, and not all developers can install mortgages in it with high quality.

The best base is metal pipes for the fence– strong, technological in installation and durable. On a metal frame, you can easily fix any enclosing material - wood, profiled steel sheet, mesh, cellular polycarbonate, asbestos or cement-bonded sheets.

Budget developers are often stopped high price metal. However, comparing the life of a metal fence with a wooden one, you will see the opposite.

Metal poles and veins will last at least 50 years, while the wooden frame of the fence during this period you will have to replace 3-4 times with all the ensuing costs.

Profile or round pipe for the fence. What to choose?

From the point of view of science that studies the resistance of materials (sopromat), the most advantageous is the round section of the pipe. With a minimum of material, it provides maximum rigidity.

If we take into account the ease of installation, then round pipes are inferior to profile ones. Rectangular racks and girders are more convenient to cut and join by welding. A flat contact surface allows you to fix all the elements of the fence more tightly and more rigidly than a round one.

As we have already said, a round pipe with the same weight is stronger than a profile pipe for bending. Therefore, if you decide to buy round-section racks for the fence, you will save money by reducing the weight of the metal. In addition, it is more convenient to install a round pipe in soft soil by screwing it in with a collar.

What pipe sizes to choose for racks and girders?

It all depends on the height of the fence, the type of facing material, the pitch of the racks and the strength of the wind.

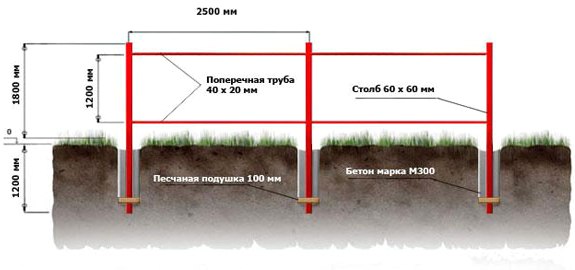

If the fence of the site is within 1.8 - 2.2 meters, then the profile pipe for the fence from corrugated board should have a section of 80x80 mm (wall thickness 3 mm).

If a round pipe is used, a diameter of 60 mm (wall 3 mm) will suffice. With the option of a fence without a foundation, it will be necessary to bury metal poles in soft soil by at least 1.2 meters, and in dense soil by 80-90 cm.

The pitch of the fence posts is of great importance. Optimal - 2.5 meters. In an area with strong gusty winds, it should be reduced to 2 meters.

For low fences (less than 1.5 meters), a square pipe 40x40x2 mm or 60x60x2 mm with veins with a section of 30x20x2 mm or 40x20x2 mm can be used.

Approximate prices for pipes of different sizes

The range of rolled metal and the choice of steel pipe manufacturers today is very wide. Therefore, before preparing material for the fence frame, you should familiarize yourself with market prices and estimate the optimal budget for the future fence.

The most convenient for frame calculations are prices for pipes calculated per linear meter of length, and not per ton. Having determined the total footage of the racks and veins of the fence, you can easily calculate their cost.

Rectangular metal pipes for fence posts with a cross section of 40x60 mm and a 2 mm wall are sold at 110-120 rubles per 1 rm. For a more powerful fence, you will need racks with a section of 80x80 mm (3 mm wall). They can be bought at a price of 260 - 290 rubles / pm.

A profiled square pipe with sides of 100x100 mm and a wall thickness of 3 mm is offered on the market at prices starting from 360 rubles/rm.

The size of the veins (purlins) to which the profiled sheet is attached is always less than the section of the pillars. The main task of these structures is to distribute the weight of the cladding and transfer it to the vertical racks.

When designing a fence from corrugated board up to 2 meters high, a tubular profile 40x20 mm (wall 2 mm) is most often taken as girders. His average cost depending on the region of sales is in the range from 66 to 74 rubles. for 1 pm

For higher and loaded fences, runs from a pipe with a section of 60x30 mm (wall 2-2.5 mm) are used. Their purchase will cost from 95 rubles per 1 running meter of the profile.

For round steel electric-welded pipes, the average cost per linear meter is as follows:

- 51 mm (wall 3) - from 136 rubles;

- 57 mm (wall 3 mm) - from 143 rubles;

- 60x3 mm - from 160 rubles;

- 76x3 mm - from 195 rubles;

- 89x3 mm - 242 rubles;

- 102x3 mm - 276 rubles.

Features of installing a fence frame

Having decided which pipes are best used for the fence and making a sketch of the docking nodes, you can proceed with the installation. At the same time, it must be remembered that the main enemies of a solid metal fence are wind and soil. Therefore, pipe-racks are best embedded in monolithic concrete, even in the most economical "hole" way.

Simply driving or screwing pipes into the ground for a high fence is not the best way. Unstable soil gets wet, dries up, freezes. As a result, the fence frame may warp or tilt. The concrete "anchor" will not allow the site fence to lose stability or change its geometric shape.

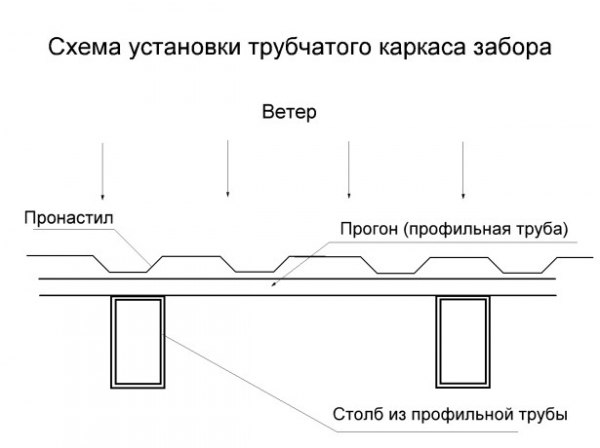

The profile pipe used for racks must be turned with the wide side perpendicular to the cladding. This will maximize the rigidity of the posts with respect to the wind tending to bend the wide "sail" of the fence.

Fastening the profiled sheet on bolts to the profile pipe 40x20

Unlike a solid fence made of profiled sheet, the installation of a frame made of pipes for a steel mesh fence is less responsible. Even a hurricane wind is not terrible for this design, because the mesh does not create a lot of aerodynamic resistance.

Here main task is to ensure the stability of the base, therefore, sufficient penetration into the ground and concreting of the pillars - mandatory conditions stability of the entire structure.

Add to bookmarks

Installation of metal pipes during the construction of a corrugated fence

IN Lately Increasingly, fences made of corrugated board began to be installed both for fencing industrial, commercial and construction sites, and for fencing private land and household plots. Such popularity is due to the availability of materials, simplicity and relatively high speed of erection of such fences. What materials are best used when building such a fence with your own hands?

One of the most important parts of corrugated fencing are support posts, which are most often made of round or profiled pipes.

How should pipe columns be installed so that they securely and firmly hold the entire fence structure?

Necessary materials and tools

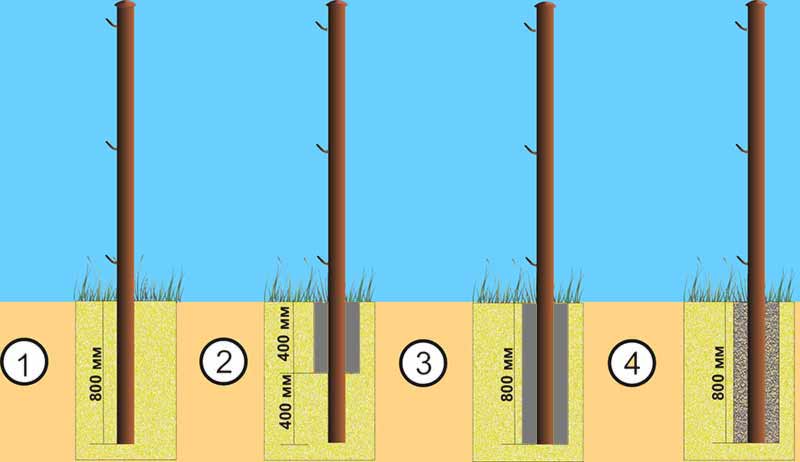

Methods for installing fence posts: 1. Driving the posts into the ground, 2. Partial concreting of the fence post, 3. Full concreting, 4. Ramming (butting) with crushed stone.

The main material, of course, is a round metal (preferably steel) pipe or its profiled version. A round pipe is more suitable for fences made of corrugated board, in which through gaps are foreseen between the sheets of the latter, where the columns will be located. The profile pipe is used in the construction of a continuous protective fabric. The diameter of a round pipe should start from 6 cm, and the width of the metal profile should be from 4-5 cm. You will also need a tool for cutting pipes: manual (hacksaw, pipe cutter, etc.) or special (electric welding or gas cutter). An electric welding invector apparatus will also be needed to attach other metal parts of the fence to the columns. In addition, you will need a tool for digging trenches and holes for the foundation, for mixing cement mortar (shovels, mortar containers, electric mortar mixer, etc.).

Calculation of the required length and number of pillars

To build a fence with your own hands, you first need to calculate its length, from which you start when counting required amount columns. In regions where there is no hurricane gusty wind, the columns can be located at a distance of 3 m from each other. If it is necessary to strengthen the fence structure with your own hands, this distance can be reduced up to 2 m. It should be understood that a solid fence made of corrugated sheets has a high windage coefficient, and therefore you should not save too much on materials. The strength and integrity of the future structure depends on their quality and correct installation.

Given the average height of the fence (about 2 m) and the depth of the ground (about 1 m), the length of each post should be about 3 m. In this way, you can purchase standard 6-meter pipes and cut them in half. It should also be noted that when building a fence from corrugated board with your own hands, you can use thinner metal profiled pipes as longitudinal strips, to which the sheet material will be attached. It is also very easy to calculate the required length of this metal profile, knowing how long the entire fence will be.

Digging and installation of columns from pipes

What depth of digging metal columns into the ground is needed in a particular area depends on the strength of the winds in a particular region. However, it can be argued that a meter depth into the ground will be quite enough. Fencing from corrugated board is best done on a cement foundation. Therefore, installing a fence with your own hands should begin with digging a trench for the foundation and installing formwork. At the place where the metal columns are installed, the foundation needs to be slightly expanded to form square bases for them. It is necessary to install the columns along a stretched cord to ensure a flat and straight plane of the future protective fabric.

After digging in the deepening pipes internal cavity formwork is poured with cement mortar. In this case, it is first necessary to maintain the column in an even vertical position by eye, and then accurately align it with a level. The cement mortar must be of high quality, because the entire fence will be held on these columns. After installing and leveling the latter, longitudinal strips can be attached to them. When used as metal pipes, they are welded using electric welding.

After installing the metal columns holding the fence, it is necessary to process them accordingly, protecting them from corrosion damage. For this, either a special protective primer or water-based, anti-corrosion paint is used. Strongly installed metal poles will be a reliable guarantee that the corrugated board fence will be reliable and durable.

What is preferable to use as corrugated fence posts? 99% will answer this question unequivocally - metal pipe. And absolutely right. steel pipe is the most economical and durable material with sufficient strength for bending (primarily) loads.

The next question is: which pipe is better to use - round or square? Everything is not so clear here. Opinions are divided roughly evenly. We present our vision in this article. this issue. We leave the issues of aesthetics and design outside the brackets - "There are no comrades for taste and color," as they say ... The issues of strength calculation of fence posts are discussed in detail in another article.

So, a square pipe has, undoubtedly, a large bending strength. Its moment of resistance is approximately 1.7 times larger than a round pipe with similar parameters (outer diameter and wall thickness). This is if you put the pole parallel to the plane of the fence, as 99% of developers do. (By the way, if you put the posts diagonally - at an angle to the plane of the fence, the increase in the moment of resistance will be only 1.2 times compared to a round pipe.)

However, this installation method has a rather significant drawback: In the place where the log is attached to the pole, a corrosion center is inevitably formed, which is almost impossible to stop or prevent. The fact is that in the place where the pipes overlap, a windproof cavity is formed where moisture is constantly present (after rain) and excellent access to oxygen. And these are two conditions under which the metal corrodes extremely quickly. The presence of a weld only exacerbates the problem. In a few years, the welded joint is completely destroyed and the fence needs to be repaired or replaced. The most annoying thing is that this place cannot be defended or at least slow down the rate of destruction. Metal corrodes from the inside!

Many people get out of the situation by cutting the fence lags to a multiple of the step of the fence posts and welding them end-to-end to each post. However, in addition to significantly greater labor costs (and the cost of such installation), the stiffness of the load-bearing structure in the fence plane and its strength are sharply reduced. The main loaded elements of such a design are just welds, and this is wrong from an engineering point of view. In winter, the forces of frost heaving can raise some of the pillars. Welded joints are destroyed and work like hinges (do not work). Among other things, it is required high quality welding work, because it is necessary to provide a sealed weld to avoid corrosion problems already inside the joist pipe.

Many mistakenly believe that a corrugated sheet gives additional structural rigidity. Unfortunately, this is not so. When the fence is skewed, the sheet is simply torn at the fastener points.

In addition to the above main drawback of square pillars, others should be noted:

- The complexity of the installation increases: in addition to ensuring verticality, it is necessary to ensure that one face of the square is in the same plane as the fence line.

- The high cost of a square pipe - a pipe weighs 30% more than a similar round pipe, and costs about 35% more

- The presence of a weld. Pipes of square (rectangular) section are produced only by welded technology. On one side there is a welded seam for the entire length of the pipe. The pipe begins to actively corrode, and the coloring practically does not prevent the occurrence of corrosion along the weld.

Logs to such pillars are overlapped with two short seams at the top and bottom of the log. The connection turns out to be purged, easily protected from corrosion by paint and serves as long years and decades. The welded seam has sufficient tensile strength (more than 1.5 tons per log). This is 15 times the load caused by a storm wind (25 m/s, for a 2 m high fence with a post spacing of 2.5 m). Due to the fact that the logs are not cut, the load-bearing structure of the fence is as rigid as possible and prevents a single column from sticking out of the ground. The pillar, in fact, is kept from bulging by two neighboring ones.

The most optimal, perhaps even the best, solution is to use tubing pipe fence posts. It is thick-walled and seamless, made of high-strength steel (yield strength reaches 116 kgf/mm2, which is 5.5 times higher than conventional pipes). Due to the high strength of steel, such poles are much stronger than a commensurate square one, and they cost about 2 times cheaper. Fences 4 meters high or more can be installed on tubing poles!

Prices for tubing poles and other materials for the construction of the fence:

Add to bookmarks

Fence from profile pipes

Beautiful gates and a fence are the first thing that characterizes the owner and his house. The fence is made from various materials, but the product using a metal profile is considered the highest quality.

Fences made of profiled metal structures are particularly durable, reliable and attractive in appearance.

The profile pipe is used both as columns with the subsequent fastening of a professional flooring on them, and as components of fence sections. The latter option is especially popular for urban architecture: public buildings, airports, parking lots. Sectional fences are also used by summer residents for their land plots. Due to the transparency of this fence, sunlight easily penetrates the garden plot. Climbing plants planted at the base of the fence can beautifully fill in the gaps between the elements of the section, creating the effect of a "living fence".

Profiled pipes for fence posts

Is an great alternative concrete or brick columns of the fence. For the construction of such a fence requires less labor and finance.

Profiled pipe is a hollow structure, round or rectangular section with a thin wall. In frequent cases, straight and bent profiles are used to create an artistic beautiful design. For columns, square profiles are most often taken. Their advantage is that any fencing material is easier to attach to such pipes: corrugated board, wooden logs, etc.

Scheme of a fence from profiled pipes with dimensions.

The strength and quality of the fence depends on its proper installation. Pillars from a profile pipe should be installed no less than 3 meters apart. This will create good conditions for docking runs between columns. The larger the spans between the columns, the more precarious the design of the fence itself will be. Jumpers from the profile are installed for subsequent fastening of boards, corrugated board, polycarbonate or other materials on them. Moreover, the wide side of the crossbar should be located close to the columns, thereby ensuring the rigidity of the entire fence. For a high fence up to 2 meters, there must be at least two jumpers. If the fence is over 2 meters, then three crossbars are required for reinforcement.

If the fence will consist of corrugated board, then the posts should be made of a profile pipe 50 x 50 mm or 60 x 60 mm in cross section. As transverse guides, take pipes of rectangular section 40 x 20 mm.

Under each column, a concrete foundation should be made. The foundation mixture is prepared in the following proportions: 4 parts of crushed stone, 3 parts of sand, 1 part of cement. All this mixture is gradually poured into 10 liters of water and mixed in a concrete mixer. The depth of the pit under the foundation should be at least 1 m, and be 30 cm in diameter. After the pits are filled with concrete, pillars are lowered into them to a depth of 50-70 cm.

Several options for fixing profiled pipes for the fence.

Installation of profile pipes is carried out by bolting or welding at the installation sites. The corrugated fence is fastened with galvanized self-tapping screws of the same color as the fence material.

Profile poles found wide application to install gates. For cars, the width of the gate should be about 3 meters. For a trailer, truck or tractor, the passage width must be at least 4 meters.

Other sizes of profile pipes can be used for the fence. It depends on the desire of the owner and on financial possibilities.

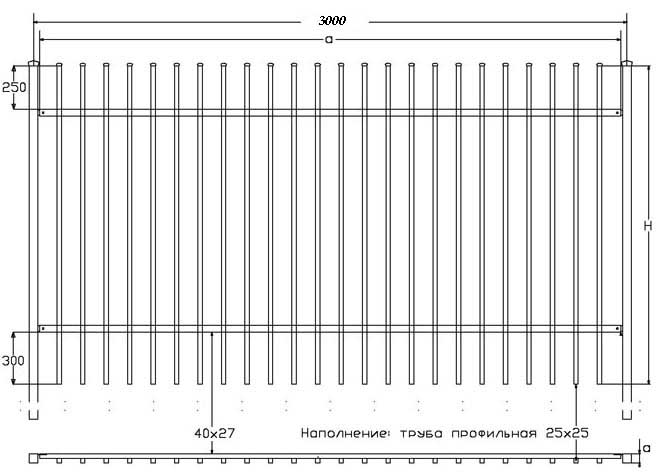

Intaking sections from profile pipes

Welded profile sections are gaining more and more popularity. A sectional fence is a metal fence made of prefabricated sections, which are fixed on posts by welding. In this case, we can safely say that the fence was not made using a profile pipe, but completely welded from them. Such fences are more expensive and less used. Ready-made sections are on sale, but they can also be ordered individually.

The advantage of welded sections is that they are easy and quick to install. These structures are welded together at the site and fastened by welding to pre-installed poles. It is better to choose the latter with a profile of 80 x 80 mm. For profile fence sections, a 20 x 20 mm or 25 x 25 mm pipe is used.

An example of a finished profiled pipe section. Such sections can be purchased ready-made.

To install a sectional fence, it is best to use a concrete foundation. This will increase the durability of the fence.

Sectional fencing can consist of a single profile, or with the use of enclosing material. The latter acts as a metal profile with artistic forging elements. This closed version used by customers who want to protect the estate from prying eyes.

Advantages of fences from a profile pipe:

- Strength and durability. resistance to any negative impacts: corrosion, wind, temperature difference, mechanical damage.

- The possibility of using a metal profile in combination with concrete, brick and other materials.

- High wear resistance.

- Lightweight design and easy installation.

- Minimum maintenance.

- Ensuring transparency and illumination.

- Attractive neat look.

It is best to use a profile pipe as poles and crossbars in combination with corrugated board or other material. Such a decision would be more reasonable and economical.

Profile fence is great option not only for suburban area, but also private houses, various public institutions. This fence is lightweight, durable and attractive design.

Each owner of the site wants to install a high-quality fence in order to secure their territory.

The most critical stage of installation is the installation of the support.

By following the rules for installing pillars, you can build a reliable fence in short time. Today we will talk about which fence posts to choose.

Which pipes to choose for the fence

There are several types of pipes that are suitable for building a fence. It can be metal, asbestos-cement or plastic pipes. There is no single answer to the question of which pipes are better.

What pipe do you need? For a fence up to 1.5 meters high, without a foundation, a pipe with a section of 50x30x2, 50x50x2 and 60x30x2 is suitable. This size allows you to withstand the load of metal structures when spot pouring pillars.

For a fence with a foundation, pipes measuring 60x60x20 or 60x40x2 are used. The poles are installed 3 meters long, since 1m must be deepened into the ground.

Pillars from asbestos-cement pipes

First you need to decide which pipe to make fence posts from. Asbestos-cement pipes, for example, are well suited for installing a chain-link mesh, as well as for connecting wooden fence spans. Installation of pillars is carried out by concreting.

Advantages

- relatively inexpensive cost, cheaper than the same metal ones;

- withstand heavy loads;

- rotting and corrosion, pipes practically do not damage.

disadvantages

- if water gets inside the pipe will burst;

- Another significant drawback of pipes is their fragility. This property somewhat complicates the transportation and installation of pipes.

$ Price

The cost of asbestos-cement pipes is 78 rubles / running meter.

metal poles

It is convenient to use such poles for fastening fence structures, including welding.

Advantages

- the poles are rigid and durable, withstand heavy loads;

- durability (service life 20 years);

- manufacturability, any structural elements can be welded to them.

$ Price

Metal pipes can be purchased at a price of 250 rubles apiece.

Plastic poles

Advantages

- modern plastic pipes are devoid of such a disadvantage as corrosion;

- frost-resistant;

- do not deteriorate from prolonged exposure to ultraviolet radiation.

The poles are suitable for wooden or plastic structures, the chain-link mesh will look great.

What diameter will fit?

Basically, pipes are chosen with the following parameters: length - 2.5-3 meters, diameter - 50-150 mm, wall thickness - 3-6 mm. Plastic pipes of other sizes are also used, it depends on the requirements for the reliability of the fence and the planned load on the supports.

$ Price

The cost is 122 rubles.

Pole installation

Installation usually begins with the installation of corner posts, then the installation of intermediate posts is already underway.

In the installation of poles important role soil plays.

- If the post is to be installed in non-porous soil, then holes do not need to be prepared. It is enough to hammer the post into the ground to a depth of 1.5-2m. A soil that is not subject to frost heaving is called non-rocking. That is, such soil does not increase in volume as a result of freezing.

- Heaving soil will require well drilling. This is the most labor intensive step. The most affordable option would be to carry out this work with a garden drill. In order to facilitate the drilling process, water is poured into the hole for 20 minutes.

Some experts recommend refraining from concreting pillars. When the space around the post is filled with concrete, a hard shell is formed, which, when frozen, will exert the same pressure as the post itself. Instead of concrete in this case, it is better to use fine-grained gravel.

How to score a pole? The driving method is the easiest to perform, it is well suited for mounting metal poles. With the help of a sledgehammer, the post is driven into the ground by 1 meter.

IMPORTANT! Proper installation of poles is the key to the reliability and durability of the fence.

Remember that it is better to spend more time and conduct a quality installation than to repair the entire structure soon.