Protections from a pipe round. What metal pipes for fences are best to use

Fence posts, according to experts, should be metal. They have many advantages:

- Increased strength;

- Rigidity;

- Long service life;

- Lack of special care;

- Beautiful appearance.

All these properties are very important when choosing fence posts.

This is what fence posts 60 x 60 made of metal look like

They must be taken into account when choosing supports for the future fence. In most cases, they use a profile pipe of different sections:

- 80 x 80;

- 60 x 60.

Choosing a step between columns

The optimal distance between the fence posts is 2.5 meters. This makes it possible to accurately set horizontal lags when their length reaches three meters. Usually all steel pipes are painted and treated with an anti-corrosion primer. In principle, you can do without painting work. In this matter leading role plays the financial condition of the owner of the fence.

The standard height of a metal pipe does not exceed three meters. From practical experience it is known that best pipes for fixing fence sections from the different material are profile metal pipes with a section of 60x60. Of course, pipes of a different diameter can be installed, but the size of 60x60 is considered the best solution, since some fences may have a large windage, for example,.

profile pipe

Dimensions and characteristics of pillars 60 x 60

In order to have more reliable and very durable fence posts, it is best to mount profile section posts with dimensions of at least 60x60 mm.

The price of such a pole does not exceed the cost of a round pipe, however, the appearance of such a support looks much better. During installation, profile poles 60x60 are much more convenient, it is easy to fix additional parts on them, as well as fences.

To reduce the price, you can install used pipes 60x60. The service life of such pipes is quite high, and the strength is not lower than that of new products. Artistic forging elements can be welded to such pipes. They are easy to attach to.

- Decking;

IN last years corrugated board for fencing, in which posts from a profile of 60 x 60 mm are installed, has become very popular.

It looks like a fence made of corrugated board with poles 60 by 60 mm

The reasons for this popularity are:

- Availability;

- Ease of installation;

- The speed of work;

- Appearance;

- Many years of operation.

Implementation of pipes for fencing

When determining the price of fence posts from a profile pipe, the following are taken into account:

- wall thickness;

- Diameter;

- Length.

The pipe is considered the most popular, the length of which reaches three meters with a wall thickness of 5 mm. In this case, the diameter of the pipe can reach 150 mm. You can buy such poles in online stores, as well as in the construction market.

square poles

Of course, support poles can be installed by yourself different shapes and various sizes. However, square-section metal poles are very popular with private individuals.

Advantages

- Such a pipe practically does not bend;

- It is very easy to fix any details on it. It is much easier to attach logs and intake sections to a profile metal pipe than to a round pipe;

- Easy to transport for future installation. They are easy to transport on any freight transport;

- beautiful design matching modern style. The square pipe gives the fence a respectable look;

- Versatility. Pillars having a square section can be used for fences of any type. They look great with a variety of materials:

- Decking;

- Mesh netting;

- Forged details.

Such metal poles are designed for long term operation. This is especially true for galvanized poles.  In principle, ordinary profile posts will stand long years, if they are coated with an anti-corrosion compound, and closed from above with special caps. Such a detail will protect the support from moisture ingress into the pipe. As a result, the service life of the support pillars will increase several times.

In principle, ordinary profile posts will stand long years, if they are coated with an anti-corrosion compound, and closed from above with special caps. Such a detail will protect the support from moisture ingress into the pipe. As a result, the service life of the support pillars will increase several times.

Manufacturing

To obtain a square profile, for example, 60x60 mm, the pipe is compressed round shape. To do this, it is rolled through the rolls of a rolling mill. In production, the formation of such products is also carried out from several pipe sections that are welded together. Of course, this method has a lower labor intensity, so the price of the finished product is much reduced.

Of course, rolled poles cost a lot more than welded poles. They also differ in increased strength. In this case, each fence owner himself chooses the material suitable for him.

Pipe dimensions

When the question of the size of the future column comes up, the following must be taken into account:

- Height;

If you want to block a section two meters long, a 60 x 60 mm pipe and a 3 mm wall will suffice. The circular support should be 60 mm in diameter with a 3 mm wall. When a fence is installed without a foundation, steel supports must be immersed in ordinary soil to a depth of more than 1.2 meters. If the soil is dense, the size of the recess should reach a maximum of 90 cm.

The pitch of the pillars is also important. The best value is 2.5 meters. When the fence is mounted in areas strong winds, the step size decreases, and becomes equal to two meters.

Enclosing structures made of corrugated board have gained popularity among consumers due to their strength, durability, presentability and affordability. But their operational properties largely depend on the quality of the construction of the supporting frame. The material for its manufacture must be resistant to loads, influence environment, easy to process and affordable. These characteristics are possessed by a profile pipe for a fence made of corrugated board.

A profile pipe is a product of building rolled metal, made from carbon or of stainless steel. The product has a square or rectangular hole. It is made by deformation of a round welded pipe in a cold or hot way. The formation of the section is carried out by exposing the product to special rolls.

Suchfence pipes(construction of supports, crossbeams), construction of building frames, ceilings, installation of masts and other structures resistant to.

Benefits of using

When arranging a fence, it is important to know which pipes are better: profile or round. In this case, all aspects should be taken into account. Round products have a high resistance to mechanical stress. The shape of their section provides the supports with maximum rigidity even with a small thickness of the material.

But profile pipes are much more convenient than their round counterparts in installation. They have a flat surface, which facilitates their cutting, joining, fixing..

The profiled pipes used for the construction of the fence frame from the profiled sheet have the following advantages:

- high strength;

- long operational period;

- speed, ease of installation;

- unpretentiousness in care;

- an extensive range of products (they are various lengths, sections);

- affordable cost.

Important nuances: metal products have one drawback - they need additional processing. To reduce the risk of rusting, the product is coated with a special primer or galvanized. Also, metal supports require periodic painting.

Features of the choice of pipes for supports and the frame of the fence

As a standard, profile pipes are produced with a section from 10x10 to 500x400 mm. The wall thickness of the product is 1-22 mm. The length of the pipe can vary from 6 to 8 m.

Corrugated fence posts are selected taking into account the height of the structure, the width of the sections and the planned load (for example, gusts of wind). For a fence 1.8-2.2 m high suitable option there will be a support with a hole of 80x80 mm. In this case, the wall thickness of the profile pipe should be 3 mm.

On the fence, reaching up to 1.5 m in height, there is a square 2 mm professional pipe measuring 40x40 or 60x60 mm. It is also possible to use a rectangular product with a hole of 30x20 or 40x20 mm of the same thickness.

Please note: the spacing of the supports is also important. Optimally, it is 2.5 m. If gusty winds are often observed on the site of the fence, the posts should be installed 2 m apart.

The cost of professional pipes

Since there are many manufacturers of steel pipes, the range of products is quite extensive, it would be good to know the price range for given material in the construction market. This will allow you to calculate the cost of the building envelope and plan the budget for its construction.

To do this, you need to know which pipe will be used and how much it will be needed. The first indicator is determined based on the dimensions of the fence, and to establish the second, it is necessary to calculate the total footage of all supports and crossbars of the structure according to the drawn up drawing.

Advice: it is most convenient to make calculations for 1 m of the product.

The cost of rectangular professional pipes with a section of 40x60 mm and a thickness of 2 mm is on average 110-120 rubles / m. n. Stronger racks 80x80x3 mm will cost 260-290 rubles / m. etc., and pillars 100x100x3 mm - from 360 rubles / m. P.

For horizontal fence rails, small-section pipes are used. They evenly distribute the weight of the facing material (profiled sheet), transferring it to the supports.

Pipes 40x20x2 mm go to a 2-meter fence, which cost 66-74 rubles / m. n. When constructing higher and more massive fences, a profile of 60x30x2.5 mm is used, which will cost 95 rubles / m. P.

Technological aspects of installing supports, a frame for a fence

After drawing up a drawing of the fence, determining which section of pipes is best to use, purchasing material, proceed to the installation of the structure. First, the racks are installed. To do this, they pre-clean, level the area under the fence, make markings.

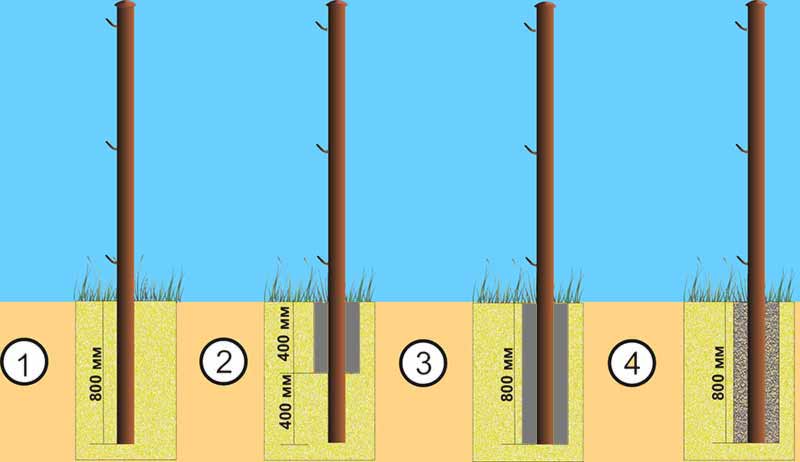

Installation of poles from a professional pipe on a fence can be carried out in several ways:

- by driving into the ground. The support is deepened into the ground by 1/3 of its length with the help of blows with a sledgehammer. Apply this method of laying the foundation for a fence on low-stony soils. The negative aspects of its use are the risk of damage to the support, the unevenness of its installation, insufficient fixation;

- using backfill and tamping. The pillars are laid in a dug / drilled shaft, and then fixed with gravel-sand backfill;

- partial concreting. lower part the supports are poured with concrete, and the rest is covered with earth, followed by ramming;

- complete pouring of concrete.

Note: the last option is the most reliable, since it provides the best fixation of the pillars. Other methods due to the instability of the soil (wetting, drying, freezing) may be ineffective, which will lead to deformation of the fence.

First, holes of the required depth are dug under the supports. The support must be deepened into soft soil by at least 1.2 m, into dense soil by 0.8-0.9 m. The bottom of the pits must be covered with a sand-gravel mixture to ensure drainage. After that, the pillars are installed in the recess, leveled and poured with concrete.

Remember: racks from a rectangular professional pipe must be mounted with a narrow side to the fence lining. This will increase the resistance of the structure to wind loads.

Lag installation

The crossbars used to fasten corrugated sheets can be installed in several ways:

- overlap. Logs are laid on top of the pillars and fixed by welding or self-tapping screws;

- butt. The crossbars are attached to the posts by welding with a tee joint (T-shaped);

- in the slot. In the vertical support, cuts are made at the bottom and top, through which the logs will pass. The fastening of the fence cross members is carried out using welding.

On a note: a fence made of corrugated board on a frame and supports made of corrugated pipes is not afraid of a strong wind, because the structure has increased strength.

The strength of the fence, its resistance to environmental influences, and other operational characteristics largely depend on the quality of the construction of the structure. Supports and crossbars made of professional pipes can significantly increase the reliability of the fence, its durability, and extend its service life.

Add to bookmarks

Installation of metal pipes during the construction of a corrugated fence

IN Lately Increasingly, fences made of corrugated board began to be installed both for fencing industrial, commercial and construction sites, and for fencing private land and household plots. Such popularity is due to the availability of materials, simplicity and relatively high speed of erection of such fences. What materials are best used when building such a fence with your own hands?

One of the most important parts of corrugated fencing are support posts, which are most often made of round or profiled pipes.

How should pipe columns be installed so that they securely and firmly hold the entire fence structure?

Necessary materials and tools

Methods for installing fence posts: 1. Driving the posts into the ground, 2. Partial concreting of the fence post, 3. Full concreting, 4. Ramming (butting) with crushed stone.

The main material, of course, is a round metal (preferably steel) pipe or its profiled version. A round pipe is more suitable for fences made of corrugated board, in which through gaps are foreseen between the sheets of the latter, where the columns will be located. The profile pipe is used in the construction of a continuous protective fabric. The diameter of a round pipe should start from 6 cm, and the width of the metal profile should be from 4-5 cm. You will also need a tool for cutting pipes: manual (hacksaw, pipe cutter, etc.) or special (electric welding or gas cutter). An electric welding invector apparatus will also be needed to attach other metal parts of the fence to the columns. In addition, you will need a tool for digging trenches and holes for the foundation, for mixing cement mortar (shovels, mortar containers, electric mortar mixer, etc.).

Calculation of the required length and number of pillars

To build a fence with your own hands, you first need to calculate its length, from which you start when counting required amount columns. In regions where there is no hurricane gusty wind, the columns can be located at a distance of 3 m from each other. If it is necessary to strengthen the fence structure with your own hands, this distance can be reduced up to 2 m. It should be understood that a solid fence made of corrugated sheets has a high windage coefficient, and therefore you should not save too much on materials. The strength and integrity of the future structure depends on their quality and correct installation.

Given the average height of the fence (about 2 m) and the depth of the ground (about 1 m), the length of each post should be about 3 m. In this way, you can purchase standard 6-meter pipes and cut them in half. It should also be noted that when building a fence from corrugated board with your own hands, you can use thinner metal profiled pipes as longitudinal strips, to which the sheet material will be attached. It is also very easy to calculate the required length of this metal profile, knowing how long the entire fence will be.

Digging and installation of columns from pipes

What depth of digging metal columns into the ground is needed in a particular area depends on the strength of the winds in a particular region. However, it can be argued that a meter depth into the ground will be quite enough. Fencing from corrugated board is best done on a cement foundation. Therefore, installing a fence with your own hands should begin with digging a trench for the foundation and installing formwork. At the place where the metal columns are installed, the foundation needs to be slightly expanded to form square bases for them. It is necessary to install the columns along a stretched cord to ensure a flat and straight plane of the future protective fabric.

After digging in the deepening pipes internal cavity formwork is poured with cement mortar. In this case, it is first necessary to maintain the column in an even vertical position by eye, and then accurately align it with a level. The cement mortar must be of high quality, because the entire fence will be held on these columns. After installing and leveling the latter, longitudinal strips can be attached to them. When used as metal pipes, they are welded using electric welding.

After installing the metal columns holding the fence, it is necessary to process them accordingly, protecting them from corrosion damage. For this, either a special protective primer or water-based, anti-corrosion paint is used. Strongly installed metal poles will be a reliable guarantee that the corrugated board fence will be reliable and durable.

The construction of a corrugated fence has some features associated with the low weight of the structure, which is subjected to significant lateral wind loads. Due to improperly selected materials, the fence can be quickly loosened by the wind, and the steel sheets can bend in an arc. Therefore, before erecting such fences with your own hands, you need to figure out which pillars should be used and how to install them correctly so that the structure stands for a long time and does not loosen.

Perhaps the most practical option- finished factory poles made of metal pipes with already welded brackets for veins

Pros and cons of profiled sheet structures

To understand the nuances of installing such a fence, you should evaluate its advantages and disadvantages. The pros are as follows:

- profiled steel sheets with a color polymer coating (usually made of polyester) look great on any type of fence and in combination with different materials;

- wide choose ;

- lightness and strength of the structure;

- simplicity and speed of fastening sheets, performed by oneself without the help of employees;

- democratic cost of construction;

- long service life (about 20 years).

The disadvantage of the fence is the burnout of the polymer coating, which makes the surface dull and inexpressive. Therefore, when choosing pipes and corrugated board for a fence, homeowners are more inclined to dark colors, whose burnout is not so noticeable.

The ease of construction is also a minus of the fence. It is well known that a light and large sail can carry away significant mass. A solid fence made of corrugated board is the same sail and it must be securely anchored in the ground on poles. Do not forget about the depth of soil freezing.

Support Structure Options

For the construction of solid fences from a profiled sheet with your own hands in private housing construction, it is customary to use the following types supports:

- metal racks from a round or profile pipe, other rolled metal;

- massive brick pillars on reinforced concrete foundations;

- wooden posts;

- supporting elements from asbestos-cement pipes.

The most popular designs are from various rolled metal, but most often they put pipes of round and rectangular cross section. This best option in terms of the price of construction / reliability of the structure. Only wooden posts will cost less, but they are not as durable and need protection from weather conditions.

The best way to hold the sail is to increase the massiveness of the structure, which is achieved by installing brick pillars, inside of which steel pipes are embedded. In addition to high reliability and durability, such a fence is aesthetically pleasing. appearance. The only drawback is the high cost of construction. Less commonly implemented is the option of using asbestos-cement pipes installed on concrete foundations. To choose suitable solution, it is worth disassembling all the options in more detail.

Choice of metal supports

For the installation of a fence sheathed with a profiled sheet, the following types of rolled metal are suitable:

- round steel pipe, ;

- metal pipes of rectangular and square section;

- equal and unequal corners;

- channels, I-beams and even rails.

Ready-made poles from a profile pipe

Ready-made poles from a profile pipe Given the high windage of the fence, rather rigid elements should be used as supports, firmly embedded in the ground with their own hands. With a fence height of up to 200 cm and an installation step of 2 m, round pipes are needed, whose outer diameter is at least 76 mm with a minimum wall thickness of 2 mm, and preferably 3 mm. Their length is selected depending on the depth of immersion in the soil and under normal conditions is at least 3 m (2 m above the ground and 1/3 part in the ground).

Under normal conditions it means ordinary sandy soil or loam, not subject to frost. In the latter case, they are lengthened in such a way as to pass through the entire freezing layer of soil and fall 0.5 m below this boundary.

The nuances of metal supports

If the height of the fence exceeds 200 cm or the span increases to 2.5-3 m, then the diameter of the pipes will also need to be larger. For a standard span of 2.5 m with a height of 200 cm, supports with an outer diameter of 89 mm and a wall thickness of 3 mm should be taken. To securely fasten a section 250 cm high and 3 m long, you will need racks even more powerful - at least 108 mm.

In recent years, supports made of rectangular pipes have become increasingly used for. For a standard span of 200 cm x 2.5 m, it is customary to use a 60x60 mm square pipe with a wall thickness of 3 mm, although some homeowners put thinner-walled products at their own peril and risk. If you are building a fence with your own hands on the side of a wasteland or other open space from strong winds, then it is appropriate to take elements of a rectangular section 80x40 mm. Wherein smaller size(in this case 40 mm) must be turned towards the wasteland in order to ensure the rigidity of the structure.

Racks made of corners or channels may not look so aesthetically pleasing, but with the right approach they will not be inferior in reliability. Equal-shelf corners on a standard section can be installed single if their size is at least 80x80 mm with a wall thickness of 6 mm. Products with a shelf width of 56-75 mm are welded in a “box” to get full-fledged fence posts. It’s the same with channels - you can put an element 18 cm wide alone, and cook “boxes” from smaller ones.

About brick pillars

Brick pillar with a profile pipe - base

Brick pillar with a profile pipe - base The installation of a respectable fence with and filling openings from corrugated board is a rather time-consuming task and will cost a lot. Although you can save money by doing the work yourself. But, having built brick pillars, you do not have to worry about their overturning by the wind.

The following types of bricks are suitable for construction:

- ceramic corpulent or hollow;

- silicate white or colored;

- special facing.

A steel profile pipe is laid inside the brick rack as a stiffening element, then transverse logs and the profiled sheet itself are attached to it. Her maximum size, which can only be inserted inside the pillar, is equal to half a brick and is 120x120 mm. But so big sizes pipes are needed in the places where the gates are suspended, and for fastening the spans, it is enough to take products of 60x60 mm. Steel strips should be welded to them for the installation of corrugated board, and the opening between the brickwork and the pipe walls should be filled with mortar.

The construction of brick pillars is carried out on reinforced concrete columnar foundations. To do this, you will have to dig holes with your own hands to the depth of freezing, hammer profile pipes into them and concrete them using a reinforcing cage. After that, the steel core is lined with bricks to a thickness of 120 cm. The length of the rack is selected so that its top is flush with the cut of the brickwork. To protect against precipitation, decorative canopies made of painted metal or concrete should be installed on the fence supports.

The use of wooden racks

The reliability of the supporting part of the hedge can be ensured by a beam with a cross section of at least 10x10 cm or a rounded log having a diameter of 12-15 cm. Of the wood species, pine, larch or spruce, pre-treated with an antiseptic composition, are best suited. The height of the pillars is selected depending on the method of installation.

Training wooden poles- coating with mastic

Training wooden poles- coating with mastic Wooden posts for corrugated fencing can be installed in two ways:

- Concrete or fill the supports in the pits, having previously processed the underground part with bituminous mastic.

- Make the underground part of the racks metal by concreted sections of profile pipes with your own hands, and then attaching wooden posts to them.

Installation of a fence made of wood with profiled sheeting is simple, and most importantly, inexpensive. Wooden crossbars are nailed between the pillars on nails, and to them with front side sheets of corrugated board are screwed with self-tapping screws. From the outside, the fence looks like a solid metal barrier, no wooden parts are visible.

Asbestos cement supports

In this case, the reliability of the supporting part is facilitated by the decent weight of asbestos-cement pipes, which, after installation, are filled from the inside with concrete. Due to this, the height of the fence with asbestos cement racks can be easily brought up to 3 m. The structure is of considerable weight, and therefore must be based on a columnar or strip foundation.

Asbestos-cement pipe

Asbestos-cement pipe As in the option with brick pillars, asbestos-cement pipe racks must be concreted into the ground to a depth of 0.8-1.5 m, depending on the height of the fence. For reliability and stability, anchoring is performed in the underground part of the supports - drilling through holes, where pieces of reinforcement of a periodic profile are then inserted. When you fill the foundation of the fence with concrete, the reinforcement will firmly connect it to the post.

To install the corrugated board, you need to make holes in the pillars with your own hands, where then insert the bolts for fastening the crossbars from steel pipes measuring 40x40 mm. If the span reaches 3 m, then the profile will have to be taken more. The profiled sheet is screwed to the profiles with self-tapping screws or self-drilling screws.

Add to bookmarks

Fence from profile pipes

Beautiful gates and a fence are the first thing that characterizes the owner and his house. The fence is made from various materials, but the product using a metal profile is considered the highest quality.

Fences made of profiled metal structures are particularly durable, reliable and attractive in appearance.

The profile pipe is used both as columns with the subsequent fastening of a professional flooring on them, and as components of fence sections. The latter option is especially popular for urban architecture: public buildings, airports, parking lots. Sectional fences are also used by summer residents for their land plots. Due to the transparency of this fence, sunlight easily penetrates the garden plot. Climbing plants planted at the base of the fence can beautifully fill the gaps between the elements of the section, creating the effect of a "living fence".

Profiled pipes for fence posts

Is an great alternative concrete or brick columns of the fence. For the construction of such a fence requires less labor and finance.

Profiled pipe is a hollow structure, round or rectangular section with a thin wall. In frequent cases, straight and bent profiles are used to create an artistic beautiful design. For columns, square profiles are most often taken. Their advantage is that any fencing material is easier to attach to such pipes: corrugated board, wooden logs, etc.

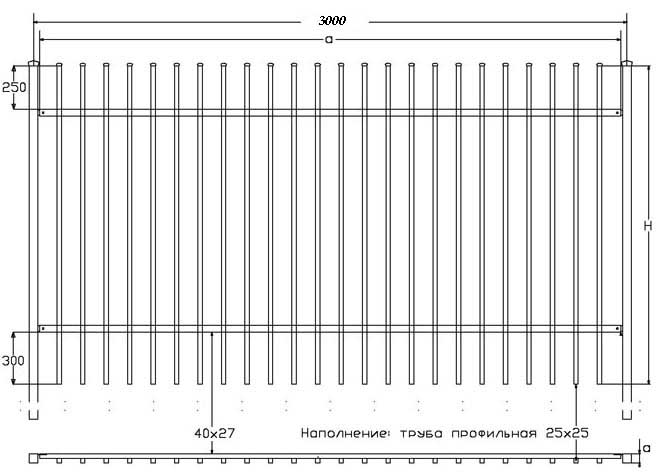

Scheme of a fence from profiled pipes with dimensions.

The strength and quality of the fence depends on its proper installation. Pillars from a profile pipe should be installed no less than 3 meters apart. This will create good conditions for docking runs between columns. The larger the spans between the columns, the more precarious the design of the fence itself will be. Jumpers from the profile are installed for subsequent fastening of boards, corrugated board, polycarbonate or other materials on them. Moreover, the wide side of the crossbar should be located close to the columns, thereby ensuring the rigidity of the entire fence. For a high fence up to 2 meters, there must be at least two jumpers. If the fence is over 2 meters, then three crossbars are required for reinforcement.

If the fence will consist of corrugated board, then the posts should be made of a profile pipe 50 x 50 mm or 60 x 60 mm in cross section. As transverse guides, take pipes of rectangular section 40 x 20 mm.

Under each column, a concrete foundation should be made. The foundation mixture is prepared in the following proportions: 4 parts of crushed stone, 3 parts of sand, 1 part of cement. All this mixture is gradually poured into 10 liters of water and mixed in a concrete mixer. The depth of the pit under the foundation should be at least 1 m, and be 30 cm in diameter. After the pits are filled with concrete, pillars are lowered into them to a depth of 50-70 cm.

Several options for fixing profiled pipes for the fence.

Installation of profile pipes is carried out by bolting or welding at the installation sites. The corrugated fence is fastened with galvanized self-tapping screws of the same color as the fence material.

Profile poles found wide application to install gates. For cars, the width of the gate should be about 3 meters. For a trailer, truck or tractor, the passage width must be at least 4 meters.

Other sizes of profile pipes can be used for the fence. It depends on the desire of the owner and on financial possibilities.

Intaking sections from profile pipes

Welded profile sections are gaining more and more popularity. A sectional fence is a metal fence made of prefabricated sections, which are fixed on posts by welding. In this case, we can safely say that the fence was not made using a profile pipe, but completely welded from them. Such fences are more expensive and less used. Ready-made sections are on sale, but they can also be ordered individually.

The advantage of welded sections is that they are easy and quick to install. These structures are welded together at the site and fastened by welding to pre-installed poles. It is better to choose the latter with a profile of 80 x 80 mm. For profile fence sections, a 20 x 20 mm or 25 x 25 mm pipe is used.

An example of a finished profiled pipe section. Such sections can be purchased ready-made.

To install a sectional fence, it is best to use a concrete foundation. This will increase the durability of the fence.

Sectional fencing can consist of a single profile, or with the use of enclosing material. The latter acts as a metal profile with artistic forging elements. This closed version used by customers who want to protect the estate from prying eyes.

Advantages of fences from a profile pipe:

- Strength and durability. resistance to any negative impacts: corrosion, wind, temperature difference, mechanical damage.

- The possibility of using a metal profile in combination with concrete, brick and other materials.

- High wear resistance.

- Lightweight design and easy installation.

- Minimum maintenance.

- Ensuring transparency and illumination.

- Attractive neat look.

It is best to use a profile pipe as poles and crossbars in combination with corrugated board or other material. Such a decision would be more reasonable and economical.

Profile fence is great option not only for suburban area, but also private houses, various public institutions. This fence is lightweight, durable and attractive design.